sfarbic

Found some matches.

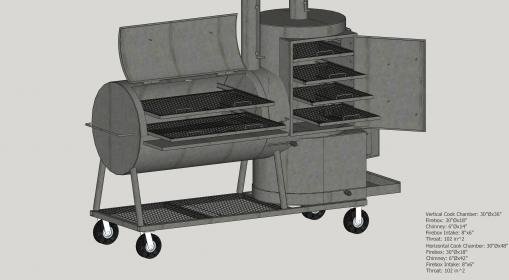

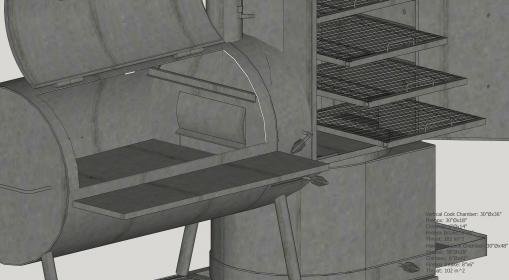

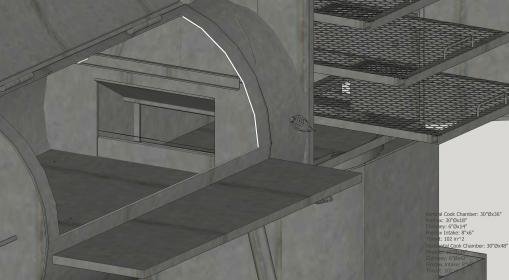

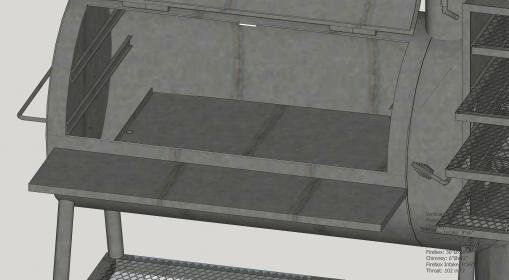

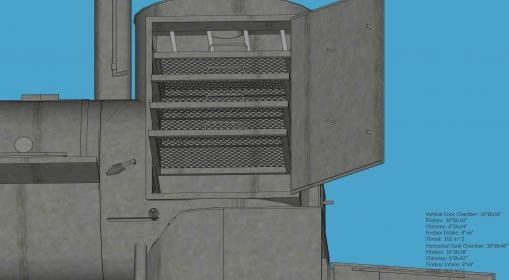

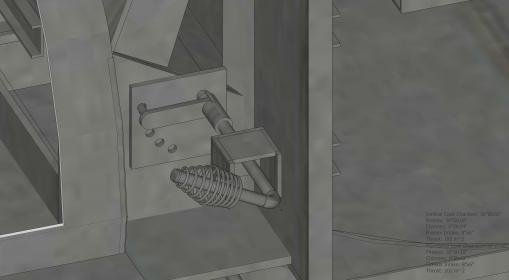

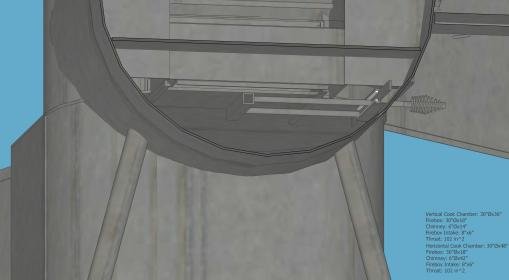

Hey everyone, I have been dreaming about building my own smoker for years now. I recently acquired (3) 30" diameter diesel tanks. One tank is 48" long and the other two are 36" long. I've read many threads online about all sorts of considerations like offset vs reverse flow, firebox size, flue size, etc. I think I have a solid idea of how I want to use the tanks so I've built a 3D model in Sketchup. The 4'-0" tank will be my main horizontal reverse flow cook chamber. One of the 3'-0" tanks will be my vertical smoker/warming box. The final 3'-0" tank will be cut in half and used as the firebox and transitional piece between the horizontal and vertical smokers. I wanted flexibility with this smoker so I can cook with just the horizontal or just the vertical or both. I will install a damper between the horizontal and vertical chambers which when open, will let smoke travel from the horizontal chamber directly into the vertical chamber. I will also build a damper between the firebox and vertical chamber so I can let smoke/heat directly into the vertical chamber without having it go through the horizontal chamber. My hope is that I will be able to use this smoker with both chambers going for large parties and use one chamber for smaller gatherings. I've included several pictures below to illustrate my plan. I wanted to post my plan and get some feed back from BBQ enthusiasts before proceeding with the build. Please let me know what you think.

Attachments

-

Reverse Flow Smoker.jpg11.1 KB · Views: 237

Reverse Flow Smoker.jpg11.1 KB · Views: 237 -

Reverse Flow Smoker2.jpg10.5 KB · Views: 240

Reverse Flow Smoker2.jpg10.5 KB · Views: 240 -

Reverse Flow Smoker3.jpg17.8 KB · Views: 237

Reverse Flow Smoker3.jpg17.8 KB · Views: 237 -

Reverse Flow Smoker8.jpg15.9 KB · Views: 235

Reverse Flow Smoker8.jpg15.9 KB · Views: 235 -

Reverse Flow Smoker9.jpg18.8 KB · Views: 235

Reverse Flow Smoker9.jpg18.8 KB · Views: 235 -

Reverse Flow Smoker11.jpg18.6 KB · Views: 237

Reverse Flow Smoker11.jpg18.6 KB · Views: 237 -

Reverse Flow Smoker12.jpg16.8 KB · Views: 238

Reverse Flow Smoker12.jpg16.8 KB · Views: 238 -

Reverse Flow Smoker7.jpg16 KB · Views: 239

Reverse Flow Smoker7.jpg16 KB · Views: 239 -

Reverse Flow Smoker11.3.jpg14.7 KB · Views: 233

Reverse Flow Smoker11.3.jpg14.7 KB · Views: 233 -

Reverse Flow Smoker11.4.jpg11.4 KB · Views: 234

Reverse Flow Smoker11.4.jpg11.4 KB · Views: 234 -

Reverse Flow Smoker15.jpg13.5 KB · Views: 237

Reverse Flow Smoker15.jpg13.5 KB · Views: 237