Shagdog

Quintessential Chatty Farker

- Joined

- Jul 1, 2013

- Location

- Grayslake, IL

Haven't really been able to find exactly what I'm looking for, so I figured.. How hard can it be? Found 304 stainless (and 316 if that's any better?) in precut bars online for about 3.50 a piece, but shipping is ridiculous, so I wanted to do a test run first, see if what I had in my head would really translate to steel. Couldn't get stainless at the local hardware store, but they had regular carbon steel in the size I was looking to buy for about $3. I know the stainless will be harder and more of a pita than regular steel, but otherwise I think it will work. This steel is 1/8 x 1/2 x 24". I bent the last 3 inches back over. May look into going 3/4 wide instead of 1/2 but just haven't decided yet.

Any ideas, suggestions, things to consider are appreciated. I'm also thinking of adding a hole about an inch above the pointy end that could receive a stainless cotter key or small stainless rod as a stopper for use when hanging.

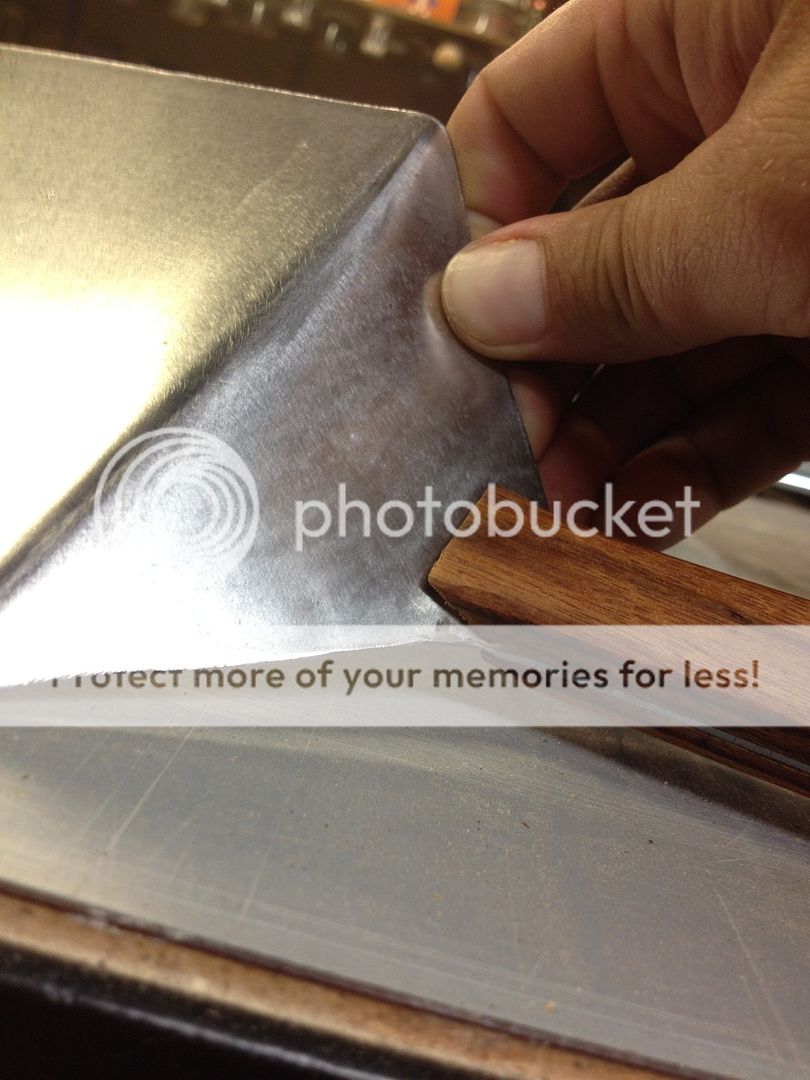

First I cut at a 45 and sharpened it on my grinding wheel.

Then I measured 3" down and put it in the vice. I hammered it down past half way.

Then I squeezed it in the vice.

And added the sausage rod from the Shirley

That's where I'm at. Going to order some steel on Monday, but I wanted to see what y'all had to say before I do.. Maybe I'm missing something. Thanks!

Any ideas, suggestions, things to consider are appreciated. I'm also thinking of adding a hole about an inch above the pointy end that could receive a stainless cotter key or small stainless rod as a stopper for use when hanging.

First I cut at a 45 and sharpened it on my grinding wheel.

Then I measured 3" down and put it in the vice. I hammered it down past half way.

Then I squeezed it in the vice.

And added the sausage rod from the Shirley

That's where I'm at. Going to order some steel on Monday, but I wanted to see what y'all had to say before I do.. Maybe I'm missing something. Thanks!

Last edited: