oifmarine2003

Babbling Farker

As a scrap guy, I come into contact with a lot of stuff. We buy tons and tons of stainless steel each year and yet, a stainless drum eluded me. Until now! I almost peed my pants when I saw this sucker come in at work! Not only was it stainless steel but it was really thick 316 stainless steel!

The only problem was it had a huge lip on it! But, nothing a plasma cutter can't fix.

Now, let's jump to the lid. I got about 100 of these lids in at work one day. I saved a couple because I thought they would make a good lid for a UDS. The only problems were they are wider than a standard 55 gallon drum and the underside was painted. But, my stainless drum has a lip on it that worked perfectly. As far as the paint, I used a wire brush on the paint and it came right off. Super easy. And cut out some aluminum (another work benefit) and fastened it to the lid to cover the two holes.

Another issue of this lid was how to shut off the exhaust when trying to snuff out the fire. We came up with a pretty good idea. We measured the inside of the exhaust and cut a piece of aluminum stock the same length. We then drilled a hole in the center of that piece of aluminum and welded it on the inside of the exhaust.

Then we took a flat piece of aluminum and traced the outside of the exhaust hole. Then cut it out.

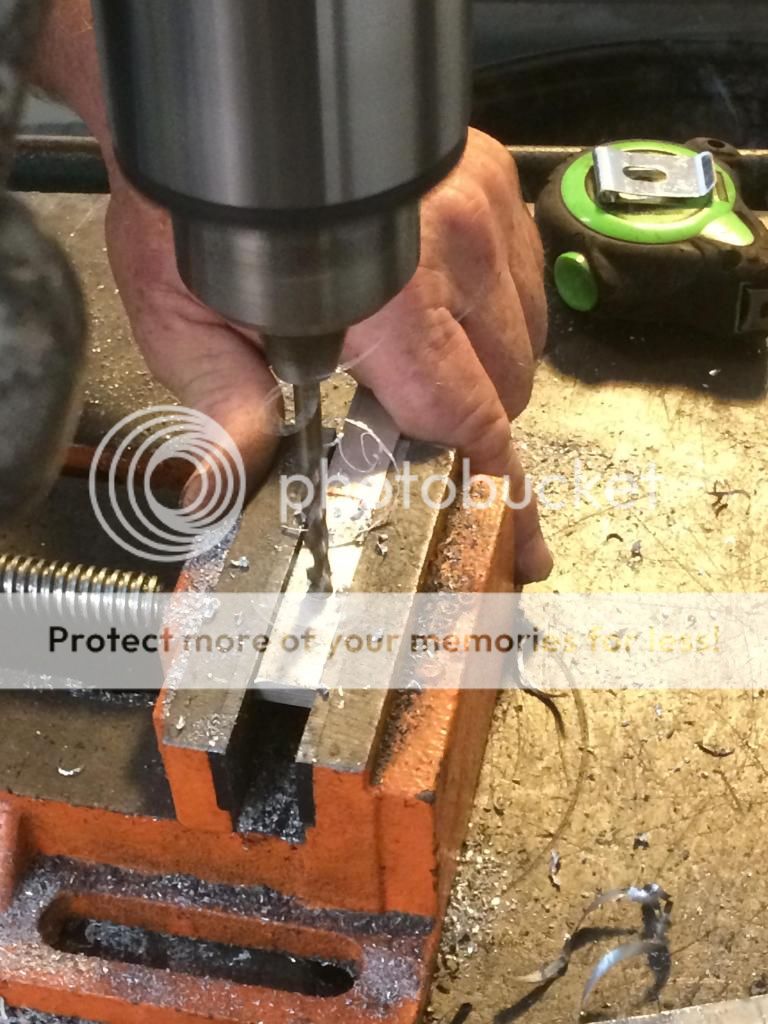

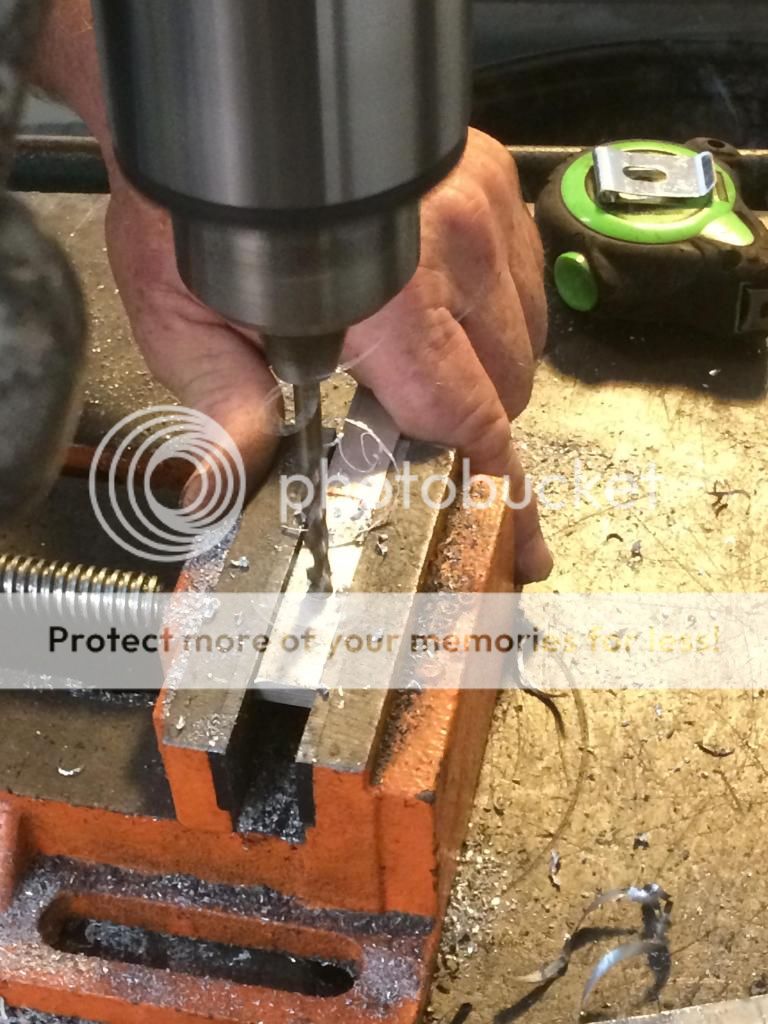

Then we drilled a hole in the circle of aluminum, inserted a carriage bolt, and used the press to press it in.

Now this circle will screw into the aluminum bar that we welded int he exhaust. Open it up when using it but when you are done and want to snuff the fire out, just screw it all the way shut. Very easy!

Next, I painted the lid with some high temperature black paint.

I drilled holes for two racks, one at 26" from the bottom and one at 34". I used 3 intakes, each with a ball valve (why not, I get them for $1.90 per pound).

On the advice of Shagdog, I decided to put a diffuser in this one. I don't have one on my other drums.

And, as an added bonus, a Weber lid rests perfectly on the newly cut lip.

And, for the temperature leads, I drilled 1/4" holes. After ruining 2 brand new bits drilling the 1" inch holes for the intakes, I decided to drill as small as holes as possible. I found 1/4" was the smallest holes that would work.

Now, nothing left but to fire Eleanor up!

SUCCESS!!!!

The only problem was it had a huge lip on it! But, nothing a plasma cutter can't fix.

Now, let's jump to the lid. I got about 100 of these lids in at work one day. I saved a couple because I thought they would make a good lid for a UDS. The only problems were they are wider than a standard 55 gallon drum and the underside was painted. But, my stainless drum has a lip on it that worked perfectly. As far as the paint, I used a wire brush on the paint and it came right off. Super easy. And cut out some aluminum (another work benefit) and fastened it to the lid to cover the two holes.

Another issue of this lid was how to shut off the exhaust when trying to snuff out the fire. We came up with a pretty good idea. We measured the inside of the exhaust and cut a piece of aluminum stock the same length. We then drilled a hole in the center of that piece of aluminum and welded it on the inside of the exhaust.

Then we took a flat piece of aluminum and traced the outside of the exhaust hole. Then cut it out.

Then we drilled a hole in the circle of aluminum, inserted a carriage bolt, and used the press to press it in.

Now this circle will screw into the aluminum bar that we welded int he exhaust. Open it up when using it but when you are done and want to snuff the fire out, just screw it all the way shut. Very easy!

Next, I painted the lid with some high temperature black paint.

I drilled holes for two racks, one at 26" from the bottom and one at 34". I used 3 intakes, each with a ball valve (why not, I get them for $1.90 per pound).

On the advice of Shagdog, I decided to put a diffuser in this one. I don't have one on my other drums.

And, as an added bonus, a Weber lid rests perfectly on the newly cut lip.

And, for the temperature leads, I drilled 1/4" holes. After ruining 2 brand new bits drilling the 1" inch holes for the intakes, I decided to drill as small as holes as possible. I found 1/4" was the smallest holes that would work.

Now, nothing left but to fire Eleanor up!

SUCCESS!!!!