Hillbilly BBQ

is one Smokin' Farker

All, as promised here is the thread of my our smoker build

We debated with family and friends and decided on the name "Chain Smoker" :mrgreen:

Plans are:

46x33x26

2" Fully insulated

4 racks - Fit 2 full size pans side by side

No Flat wheels with a turning axle

Dual Tel-Tru gauges

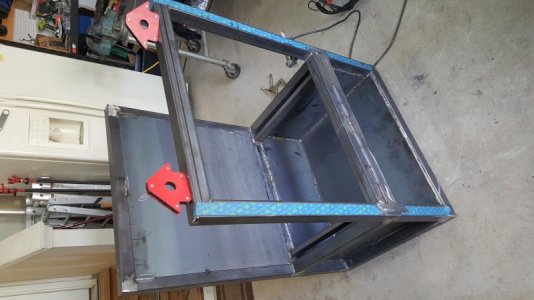

Here is day 1. Frame is almost completely boxed in. Have about an hours worth of welding to finish the plate lining the firebox. Have 1/4" Defuser plate cut and ready to go in.

Tomorrow hope to have inner skins and exhaust in. All welds on the outside are ground down ready for the outer skins. Day 3 I want to have it insulated and skins on.

Tuesday I can pick up the steel for my shelves, but will have rails built ready for them. Wednesday I would like to be building doors, Firebox and ash pan.

And I love the new 3 axis jig...wow does it make things easy! Wish I had a little more done today, but my help didnt show up today. A buddy of mine stopped by for about 2 hours and I put him to work to help me carry heavy stuff

We debated with family and friends and decided on the name "Chain Smoker" :mrgreen:

Plans are:

46x33x26

2" Fully insulated

4 racks - Fit 2 full size pans side by side

No Flat wheels with a turning axle

Dual Tel-Tru gauges

Here is day 1. Frame is almost completely boxed in. Have about an hours worth of welding to finish the plate lining the firebox. Have 1/4" Defuser plate cut and ready to go in.

Tomorrow hope to have inner skins and exhaust in. All welds on the outside are ground down ready for the outer skins. Day 3 I want to have it insulated and skins on.

Tuesday I can pick up the steel for my shelves, but will have rails built ready for them. Wednesday I would like to be building doors, Firebox and ash pan.

And I love the new 3 axis jig...wow does it make things easy! Wish I had a little more done today, but my help didnt show up today. A buddy of mine stopped by for about 2 hours and I put him to work to help me carry heavy stuff