chris1360

Knows what a fatty is.

About 5 years ago I upgraded my el-cheapo Wally World 22 inch kettle to this Chargriller. At the time I thought it would be a good grill and offset smoker combo. After trying to mod the crap out of it, and many long nights chasing temperature swings, I gave up on trying to smoke on the Chargriller. Soon after, I built a UDS and a mini UDS, so the Chargriller was demoted to high heat grilling only.

After 5 years this things is pretty beat up, rusted, and needs a face lift, badly. I really wanted to go buy a 26 inch Weber, but that cost money, and I am cheap. So the Chargriller got some love, and a few modifications to make it suit my grilling needs. Here is what I did:

Here is my worn out Chargriller after 5 years of abuse:

As you can see, the weather did not treat this thing very well, and the paint apparently was not as heat resistant as they claimed. One of my main gripes about the Chargriller was how terrible the ash catcher and charcoal rack was. I couldn’t bank the coals on the side very well because the coals would fall into the fire box, and ash went everywhere. I tried a few mods with some old scrap metal with ‘meh’ results. You can see here that it’s an absolute mess:

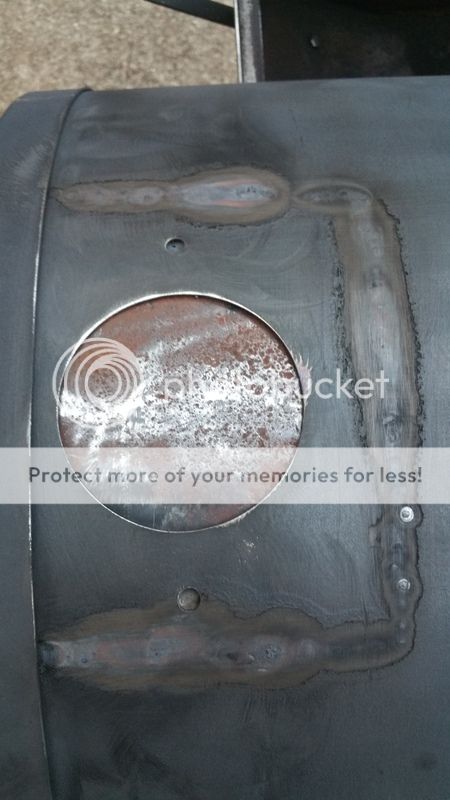

I began by stripping the whole grill down in order to start the mods and rust removal:

After 5 years this things is pretty beat up, rusted, and needs a face lift, badly. I really wanted to go buy a 26 inch Weber, but that cost money, and I am cheap. So the Chargriller got some love, and a few modifications to make it suit my grilling needs. Here is what I did:

Here is my worn out Chargriller after 5 years of abuse:

As you can see, the weather did not treat this thing very well, and the paint apparently was not as heat resistant as they claimed. One of my main gripes about the Chargriller was how terrible the ash catcher and charcoal rack was. I couldn’t bank the coals on the side very well because the coals would fall into the fire box, and ash went everywhere. I tried a few mods with some old scrap metal with ‘meh’ results. You can see here that it’s an absolute mess:

I began by stripping the whole grill down in order to start the mods and rust removal: